DKM has accumulated rich experience in helping customer establish various plastic molding factories, especially thin wall container molding factory. We can not only design and manufacture high quality thin wall container molds, but also provide special machine, robot and necessary auxiliaries to help our customer achieve excellent production capability at fraction of costs. Until now, we have accumulated many advantages in thin wall container production line:

First, to thin wall container, the most important factor is thickness, the thinner, the better, because it leads to material cost and cycle time. So our experienced engineering team spent many years on trying to cut down the thickness to 0.28mm, finally we made it.

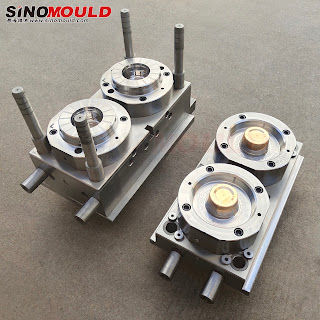

Second, short cycle time, our designers will analysis the product according to customer requirements, then try to figure out the best water channel before mold tooling. We also use cu-be on the bottom of the core to make each cavity cool quickly. What’s more, our experienced engineering team developed high speed injection molding according to thin wall box mold features. For example, 0.28mm thickness, 0.5L, 4 cavity molds, the cycle time is 3.5s.

Third, we can offer customer IML technology according to their requirements. IML products are more attractive and easier to be remembered by customers, so more and more customers want to make IML container mold. In order to help customer save labor cost and improve the production efficiency, we also can provide suitable robot per the mold and injection molding machine.

Fourth, when the mold and equipment reach customers’ factories, our experienced engineer will fly to their factories to teach and help them operate our molds and equipment to make sure they can run smoothly and stability.

If you are looking for IML container mold supplier, come to Sino, we not only offer IML container mold for you, but also offer you IML solution.

Post by Ms Mandy

Ms Mandy: 008615757610702