We are Chinese famous water dripper mould manufacturer, supplier, maker and exporter with more than 20 year experience. The

range is widely appreciated by the clients for strength, excellent performance,

reliability, efficiency and longer functional life. Available in varied sizes,

designs and specifications, the range can also be customized as per the

requirements of the customers.

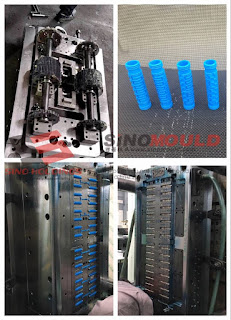

Let me take one 32 cavity water dripper die

as an example to show the advantages of our moulds.

1.Mould cavity and core steel:

Assab S136 with HRC40-44.

2.Mould inserts and slides steel:

H13, tempered with HRC42-45.

3.Mould base: P20 made in China.

4.Runner system: 8 tip Anole hot

runner turn to cold runner submarine gate.

5.Ejection system: adopts wheel

gear system to pull the slides instead of hydraulic cylinder system to reduce

cycle time and production cost.

6. Suitable machine Ton: DKM380T.

7.Cycle time: 10s.

8.Guaranteed

mould life: 5M.

9.Lead

time: 60 working days for 1st samples.

We can not only offer water dripper mould maker, but also

can offer the whole production line for the customer who are newer in plastic

injection molding industry. The whole water dripper production line includes: injection

molding machine, water dripper mould, water chiller, auto loader and so on. So

if you want to develop water dripper project, pls kindly contact me, Iam glad

to share technical points and offer best solution for you.

Post by Miss Mandy

Email: auto@sinomould.com

Skype: sino.mould