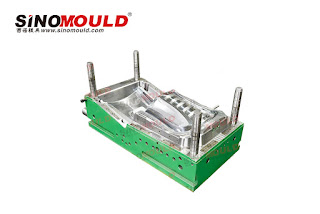

We are Chinese famous chair mold maker, manufacturer, offer, exporter and trader with more than 20 year experience. The offered chair molds cover PC chair mold, PP chair mold, gas assisted chair mold, child chair mold and so on. This article is to share our experience to help customer check what kind of chair mold is high quality and what kind of chair mold is bad quality.

Firstly check the cycle time, if the chair weight from 1700g to 2400g, the cycle time should be 35s to 50s. If the machine plastic melt and inject are with accumulators. Please check how they make the cooling channel? The cooling channel is extra in and out?

Second check the chair mold guaranteed life. Most of manufacturers will say that their molds will have one millions guaranteed life. But God now how can they guarantee. Can the mold run 1 million shorts without any flashes? Because if you accept to cut the flash by your workers heavy labor, I think you can use this mold for 10 million shorts. So you need to check the steel hardness, and in the mold if there is any parting area were welded. Normally the steel hardness should be HRC33.

Thirdly double check the parting line finishing, if there has any sharp edges? You have to check the chair mold parting line is correct or not. And know how the CNC milling the cavity and core. Are they one stage finishing or several stage finishing?

Fourth double check the wall thickness, is it even or not? The uneven thick will cause the injection not balance and also will cause the cooling time not even, which will affect the injection speed slow down and also will cause the shrinkage marks. If CNC milling is too rough, you can never get a chair with thickness even.

Fifth check the stackable. When the chair plastic design is doing, we have to check its stack ability. And you also need to consider the deform possibility of the chair moulding.

All in all, one high quality chair mold must be with short cycle time, long mould life, perfect parting line finishing, good stack ability, well air vent design, less weight but strong enough.

If you have idea want to develop chair mold or set up chair molding factory, please kindly contact me, Iam glad to offer the whole production line for you.

Whatsapp: 008615757610702