With the

development of plastic industry, more and more business men pay attention on

this industry and want to start this business. In order to meet market needs

and help those business men who want to establish plastic injection

molding factory, our company Sino Group put forward one-stop service to offer all-round

service from building injection molding

machine factory to choosing injection mould.

The whole project

includes below steps:

1. Choose suitable

factory site, design factory sketch, calculate budget

The most suitable

factory site must have power supply, water supply with convenient

transportation. The outlook can be as simple as possible to save building cost

like rectangular.

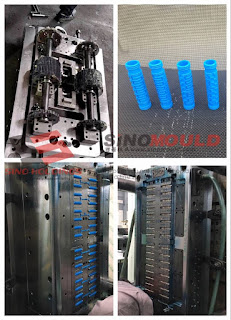

2. Workshop layout

design, figure out related machine and mould

According to the

factory drawing and the products that customer want to produce to help customer

figure out mould specification, like mould cavity, mould size with related

machine. The most important thing is meet customer production requirements with

his target budget.

3. Training for

injection moulding technology and workshop management

When mould and

machine are ready, we will arrange our engineer to go to customer’s factory to

help them install and commission the machine, and teach them how to operate our

machine and mould to let them mater the key points. What’s more, our

experienced production manager will share our manager experience with customer

to help them improve production efficiency.

4. After sale

consulting and equipment maintenance will be offered

Few customer has

experience in maintenance mould and machine with positive approach, so we

always put mould and machine instruction manual and

maintenance manual together with mould and machine when shipment. If you have any

problem with our mould and machine, just call us, we can service you at any

time.

So as long as you

have ideas, we will serve for you devoutly; As long as you have requirements,

we will make you satisfied absolutely. We warmly welcome your down visit and

would like to develop long term friendly cooperation with you and your company.

Post by Miss Mandy

Email: auto@sinomould.com

Whatsapp: 008615757610702