Lubricant bucket is widely application in lubricant industry, so it attracts investors to develop on this. SINO MOULD is professional on supplying lubricant bucket production molding equipment which contains lubricant bucket mold, injection molding machine, robot, and chiller and so on.

Lubricant bucket body mold:

Steel: P20 or 718H made in China, which could guarantee at least 1M shots

BeCu for the top of the core and top mouth of the cavity side

Injection gate: Hot runner system, Anole brand

Ejection gate: stripper way

Cavities No: 1 cavity

Structure: with optimal cooling system and air venting system.

Precision control: After each tooling step, we will check dimension by bridge coordinate measuring machine. Once it passed, then go next step. Besides, our tooling machine had DMG high speed milling, Japan Shaddic and Japan Marzark high precision lathe.

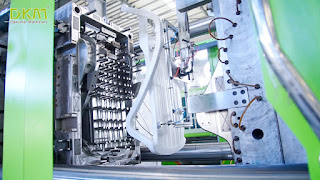

Lubricant bucket molding machine:

We suggest using servo motor injection molding machine for producing lubricant bucket production. The advantage is could save 20%-80% energy and with servo motor, action precision could ensure and will get the best injection result. And the servo system compared with traditional machine, its holding pressure is more stable and dwell time is much extended which is better for test tube molding. Besides, dynamic servo motor with a response time of only 0.05sec and machines runs at very lower noise level and operate stability.

With help of dryer, chiller and others accessories equipment, those will improve cycle time and get the best injection result. What’ more, we had machine agent in Jordan, Columbia, South Africa, Nepal, Mexico, Greece, Ukraine and others which could provide fast and convenient after-sale service and technical recommendation.

If you want to set up your own plastic lubricant bucket molding factory, pls kindly contact me, Iam glad to reply you and offer best solution for you.

Post by Ms Mandy

Whatsapp: 008615757610702