In order to ensure the plastic injection mould work normally, smoothly, lower trouble and prolong the using life of machine, user must note to maintain the mould during everyday use.

Sino has rich experience in how to maintain plastic injection mould, since we are not only Chinese famous injection mould supplier, but also injection molding company. We know every detail of mould and molding process so had accumulated rich experience in maintenance plastic injection moulds. Below are our common methods, for your reference:

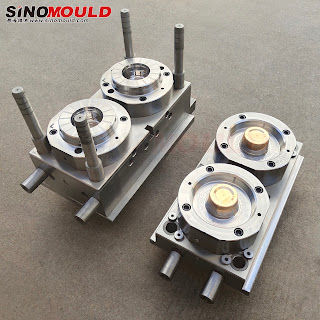

After finishing mass production, we need to check the mould in a complete inspection.

1. We should check and clean both parting surface, ensure that the cleanness of the mould.

2. Check the mould runner to ensure there is no defective material in the runner.

3. Clean venting-groove.

4. Cleansing cooling channel with PURE & sanitary Liquid, then pulling away leftover by air gun & drying channel via SIROCCO.

While in the daily mould maintenance, we also need to check the whole parts of the plastic injection molds, like the safety pin, safety screw, side guard and so on.

1. Check and test cooling channel on airproof guard.

2. Measurement of heating system under H.R. Instruction.

3. Ensuring Hydraulic C. moving under proper Conditions and w/o Oil-leak Problem.

4. Adding enough Lubricant for smooth core pulling movements.

5. Make sure lubrication of the sliding mold parts.

6. Measure hydraulic system’s pressurization.

Mould storage: after all techniques finished, physical dryness &antirust treatments are required according. Finally, fixing & storing mould under dry conditions.

Please keep in mind if we keep maintain well of the molds, the mold will become the longer life. If you are newer investor in plastic injection industry who is not professional in such industry, please kindly contact us when you have any problem, we are glad to reply you and help you with your business.

Post by Ms Mandy

Whatsapp: 008615757610702

Email: auto@sinomould.com