2022年5月29日星期日

How to Make High Performance Plastic Paint Pail Die Mold

2022年4月30日星期六

Plastic Chair Mould Making Solution

We are Chinese famous chair mold maker, manufacturer, offer, exporter and trader with more than 20 year experience. The offered chair molds cover PC chair mold, PP chair mold, gas assisted chair mold, child chair mold and so on. This article is to share our experience to help customer check what kind of chair mold is high quality and what kind of chair mold is bad quality.

Firstly check the cycle time, if the chair weight from 1700g to 2400g, the cycle time should be 35s to 50s. If the machine plastic melt and inject are with accumulators. Please check how they make the cooling channel? The cooling channel is extra in and out?

Second check the chair mold guaranteed life. Most of manufacturers will say that their molds will have one millions guaranteed life. But God now how can they guarantee. Can the mold run 1 million shorts without any flashes? Because if you accept to cut the flash by your workers heavy labor, I think you can use this mold for 10 million shorts. So you need to check the steel hardness, and in the mold if there is any parting area were welded. Normally the steel hardness should be HRC33.

Thirdly double check the parting line finishing, if there has any sharp edges? You have to check the chair mold parting line is correct or not. And know how the CNC milling the cavity and core. Are they one stage finishing or several stage finishing?

Fourth double check the wall thickness, is it even or not? The uneven thick will cause the injection not balance and also will cause the cooling time not even, which will affect the injection speed slow down and also will cause the shrinkage marks. If CNC milling is too rough, you can never get a chair with thickness even.

Fifth check the stackable. When the chair plastic design is doing, we have to check its stack ability. And you also need to consider the deform possibility of the chair moulding.

All in all, one high quality chair mold must be with short cycle time, long mould life, perfect parting line finishing, good stack ability, well air vent design, less weight but strong enough.

If you have idea want to develop chair mold or set up chair molding factory, please kindly contact me, Iam glad to offer the whole production line for you.

Whatsapp: 008615757610702

2022年3月22日星期二

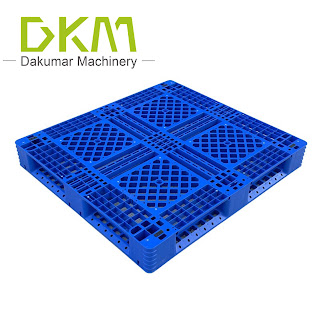

Plastic Pallet Mold Manufacturer

2022年2月27日星期日

Chinese Plastic Cap Mold Manufacturer

2022年1月26日星期三

How to Maintenance Plastic Injection Mould

In order to ensure the plastic injection mould work normally, smoothly, lower trouble and prolong the using life of machine, user must note to maintain the mould during everyday use.

Sino has rich experience in how to maintain plastic injection mould, since we are not only Chinese famous injection mould supplier, but also injection molding company. We know every detail of mould and molding process so had accumulated rich experience in maintenance plastic injection moulds. Below are our common methods, for your reference:

After finishing mass production, we need to check the mould in a complete inspection.

1. We should check and clean both parting surface, ensure that the cleanness of the mould.

2. Check the mould runner to ensure there is no defective material in the runner.

3. Clean venting-groove.

4. Cleansing cooling channel with PURE & sanitary Liquid, then pulling away leftover by air gun & drying channel via SIROCCO.

While in the daily mould maintenance, we also need to check the whole parts of the plastic injection molds, like the safety pin, safety screw, side guard and so on.

1. Check and test cooling channel on airproof guard.

2. Measurement of heating system under H.R. Instruction.

3. Ensuring Hydraulic C. moving under proper Conditions and w/o Oil-leak Problem.

4. Adding enough Lubricant for smooth core pulling movements.

5. Make sure lubrication of the sliding mold parts.

6. Measure hydraulic system’s pressurization.

Mould storage: after all techniques finished, physical dryness &antirust treatments are required according. Finally, fixing & storing mould under dry conditions.

Please keep in mind if we keep maintain well of the molds, the mold will become the longer life. If you are newer investor in plastic injection industry who is not professional in such industry, please kindly contact us when you have any problem, we are glad to reply you and help you with your business.

Post by Ms Mandy

Whatsapp: 008615757610702

Email: auto@sinomould.com

2021年12月31日星期五

Demoulding Way for Crate Moulds

There are two common demoulding ways of crate mould, one is latch locking system, another one is hydraulic cylinder system.

Below is short analysis of these two demoulding systems.

For latch locking system, when mould opens, the latch lock pulls the slides to demould, which lead to short cycle time, high efficiency, so lots of customers prefer such system. Howere, compare with hydraulic cylinder system, latch locking system has short mould life. So Sino pay high attention in lengthening the mould life of latch locking system, and has accumulated rich experience. We make inserts between latch lock and slides, if the insert was broken, it is easy to make and change. Usually, we adopt high hardness and wear-resisting steel to make inserts, and send extra inserts to customer. Latch locking system has short cycle time, so the crash pressure on parting surface is large, so we add buffer gasket or spring under stripper and slides to reduce the crash pressure.

If customer want to make thin-wall crate mould, we suggest adopt H13 or DIN1.2344 steel for core and cavity since thin-wall crate has strict required on steel hardness. The thickness of thin-wall crate is less than 1mm, when injection, the injection pressure is very large, and the clamp tonnage also large, so the steel must be hard enough to avoid deformation. Otherwise, product will has flash after long time squeezing.

For hydraulic cylinder system, it is much stable than latch locking system, since it uses oil pressure to control demoulding speed. And hydraulic cylinder is not easy to break, so its mould life is longer than latch locking system, but its cycle time is longer.

If you want to develop crate mould, and want to know more about techincal points, pls feel free to contact with me, I will offer best solution for your project.

Post by Ms Mandy

Whatsapp: 008615757610702

2021年11月30日星期二

24 Bottle Crate Mould Solution

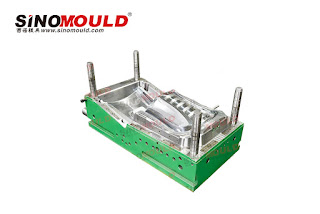

SINO MOULD is a very famous injection mold supplier in China, providing the high performacnce bottle crate mold with best molding solution. The products are dimensionally precise and are known for excellent finish. We not only offer high quality mold making, but also offer best molding solution.

We use UG, AUTOCAD, Solidworks, CATRA software to design such kind of mould. For different clients may use different softwares, before design we will confirm with our clients to meet their needs.

Below is one of 24nos. bottle crate mold case:

1. Mold cavity: 1 cavity

2. Mold dimension: 900*750*700mm

3. Product material: PP

4. Mold steel: DIN.1.2738 with Becu

5. Mold base: LKM/ SINO standard

6. Runner: 6 tip Anole hot runner (www.anole-hot-runner.com)

7. Machine tonnage: DKM520T

8. Cycle time: 36S

9. Guaranteed mold life: 1M

10. Lead time: 70 days

Bottle crate molds made by SINO has many advantages: perfect cooling system and cavity injection leads to short cycle time, fully sutomatic ejection system, well finished prodcut parting lines and surface, easy to maintance... What’s more, we have succeed in making cola bottle crate with 4 side angle lift design and 4 sides handle with hollow on the 4 side walls. So if you are interest in crate mold, come to SINO MOULD, we will satisfy you.

Whatsapp: 008615757610702

.jpg)